Hydrogenation has shaped the modern oils and fats industry for more than a century. From confectionery fats to shortenings and specialty ingredients, this process remains essential—yet increasingly regulated. This guide breaks down why hydrogenation is used, the types of hydrogenation, the products derived from palm-based oils, and the latest regulatory landscape in the U.S. and Europe.

1. Why Do We Hydrogenate Oils and Fats?

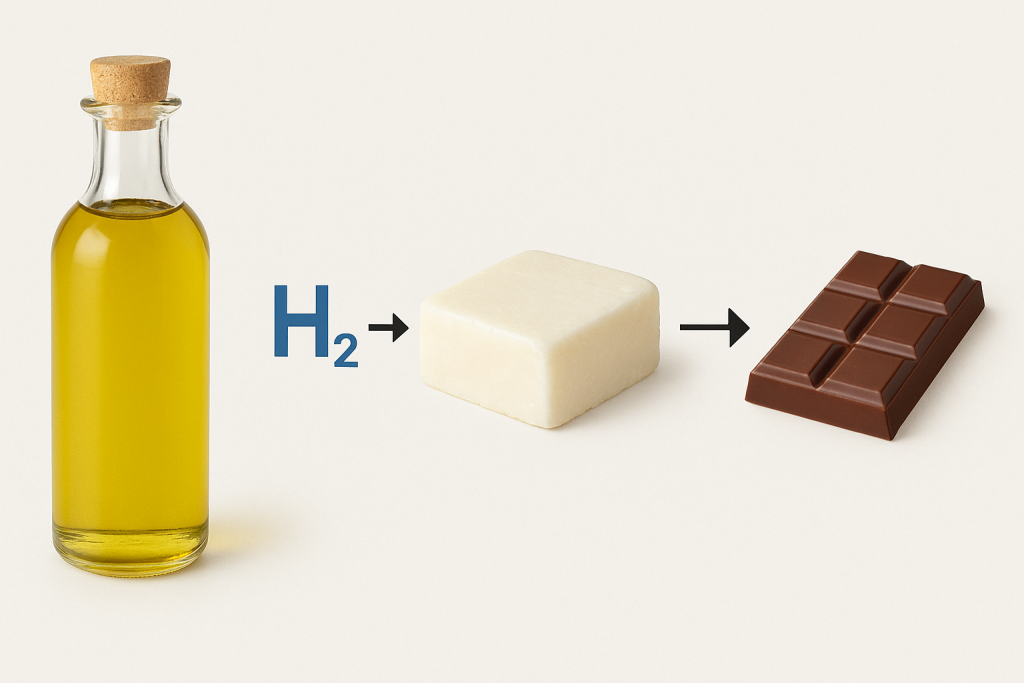

Hydrogenation is the process of adding hydrogen atoms to unsaturated fatty acids in the presence of a catalyst (usually nickel). The goals are:

🌡️ Improve Oxidative Stability

Unsaturated oils oxidize quickly, causing rancidity. Hydrogenation reduces double bonds, increasing shelf life.

🧈 Modify Melting Profile

Hydrogenation increases the melting point, making oils more solid. This is essential for:

- Bakery shortenings

- Confectionery coatings

- Margarines

- Frying fats

🏭 Create Functional Textures

Hydrogenation allows manufacturers to tailor plasticity, hardness, and crystallization behavior for specific applications.

2. Types of Hydrogenation

A. Partial Hydrogenation

- Hydrogenation stops before all double bonds are saturated.

- Creates trans fatty acids, which have been linked to cardiovascular disease.

- Once widely used for margarine and shortening, now heavily restricted or banned.

B. Full (Complete) Hydrogenation

- All double bonds are saturated.

- Produces fully saturated fats with no trans fats.

- These fats are hard and brittle, often blended or interesterified for functionality.

3. Cocoa Butter Substitutes (CBS) and Hydrogenation

Cocoa butter substitutes are fats designed to mimic the melting behavior of cocoa butter but at lower cost.

Hydrogenation in CBS

CBS is typically made from fully hydrogenated PKO or coconut oil, then blended or fractionated. Full hydrogenation ensures:

- No trans fats

- Sharp melting curve

- Snap similar to cocoa butter

4. Positive and Negative Aspects of Hydrogenated Oils

✔️ Positive Aspects

- Improved shelf life and oxidative stability

- Tailored melting profiles for bakery and confectionery

- Cost-effective alternatives to expensive fats like cocoa butter

- Full hydrogenation produces zero trans fats

❌ Negative Aspects

- Partial hydrogenation creates trans fats, linked to:

- Higher risk of coronary heart disease

- Increased LDL cholesterol

- Inflammation

- Regulatory bans require reformulation and higher production costs

- Fully hydrogenated fats can be too hard and require blending or interesterification

5. Recent Regulations on Hydrogenation in the U.S. and Europe

🇺🇸 United States

The FDA has revoked the use of partially hydrogenated oils (PHOs) in foods, declaring them no longer GRAS (Generally Recognized as Safe).

This includes:

- Removal of PHOs from standards of identity for peanut butter and canned tuna

- Revocation of PHO use in margarine, shortening, bread, rolls, and buns

🇪🇺 European Union

The EU limits industrial trans fats to no more than 2% of total fat in food products.

This aligns with WHO’s global call to eliminate industrial trans fats by 2023.

Key Point

- Partial hydrogenation is effectively banned or restricted in both regions.

- Full hydrogenation remains allowed, as it does not produce trans fats.

Conclusion

Hydrogenation remains a critical tool in the oils and fats industry—especially for confectionery, bakery, and frying applications. While partial hydrogenation has been phased out due to health concerns, full hydrogenation continues to play a major role in producing stable, functional fats such as cocoa butter substitutes.

For manufacturers, the challenge today is balancing functionality, cost, and regulatory compliance while delivering clean-label, trans‑free products.